Cast sign-making process begins with designing the sign, either based on client ideas or from scratch. We work closely with clients to ensure the final product meets their specifications.

Once the design is agreed upon, we create a version of the sign usually in acrylic, matching the exact size and design elements of the final product. Depending on complexity, the acrylic pattern may be produced by hand or using our CNC router for efficiency.

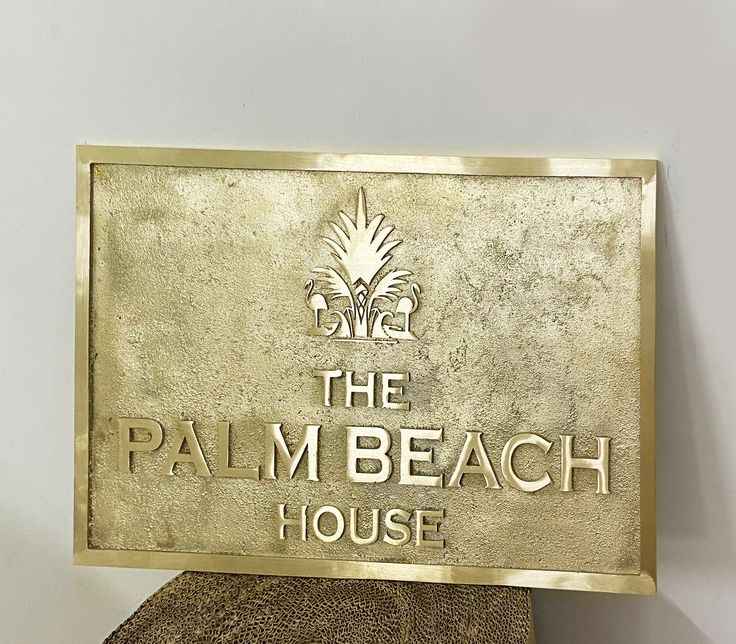

Next, we create a sand mold from the acrylic pattern into which hot metal is poured. After cooling, the molds are opened to reveal the cast sign. We then refine the sign, removing any imperfections and sharp edges.

Our signs are painted using epoxy primer and UV-resistant paint for durability. Letters and emblems are hand-finished with signwriters' enamels for a strong, uniform color that withstands the elements and UV radiation, ensuring longevity.